AI Innovation and a New Era of Responsibility in the Automotive Industry

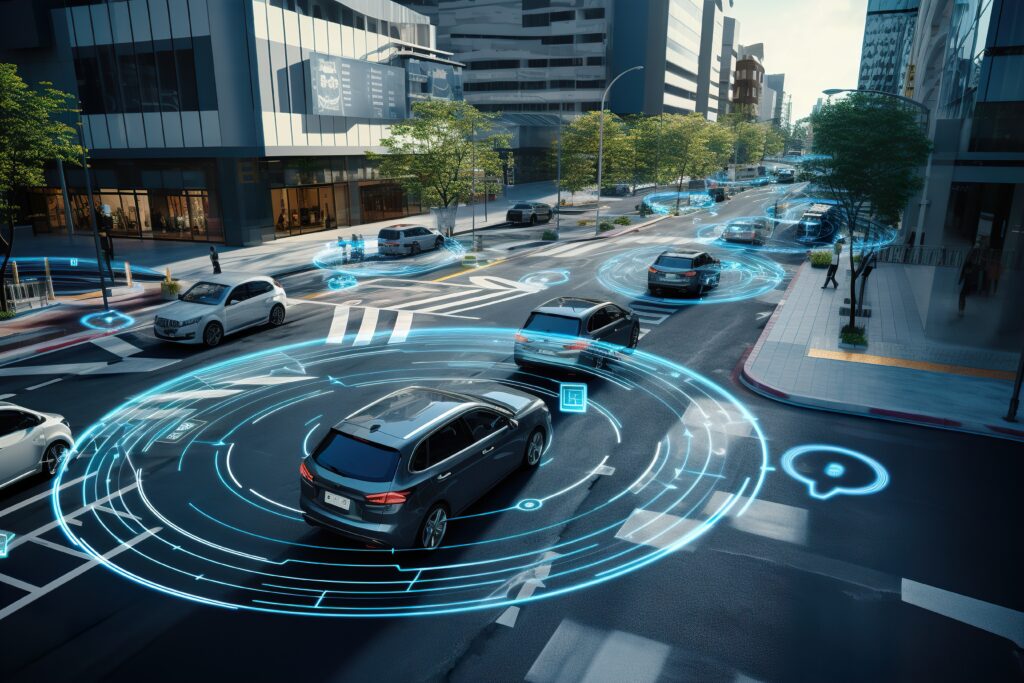

Cars are no longer just means of transportation. With the emergence of Software-Defined Vehicles (SDVs), artificial intelligence (AI) is no longer a future technology—it has already become the core of the automotive industry.

From Advanced Driver Assistance Systems (ADAS) and autonomous driving to enhancing in-vehicle user experiences, predictive maintenance, and manufacturing process innovation, there is no area untouched by AI.

However, this innovation comes with new challenges. AI’s inherent unpredictability and opacity create risks that cannot be addressed by traditional quality and safety management methods alone. Issues such as data bias, algorithm uncertainty, and performance degradation are prime examples.

Amid these changes, one international standard is attracting attention—ISO/IEC 42001, the Artificial Intelligence Management System (AIMS). This is not merely a regulation but a strategic framework for developing and operating AI safely and responsibly. Just as the automotive industry has long managed quality and risks through standards such as ISO 9001 and IATF 16949, AI governance will become the key to future competitiveness.

In particular, Tier 1 and Tier 2 suppliers should adopt this standard proactively. OEMs will expand AI management requirements across their supply chains, and compliance with ISO/IEC 42001 will determine future business opportunities.

Understanding ISO/IEC 42001 AIMS: What It Is and Why It Matters

Definition and Objectives

ISO/IEC 42001 is the international standard for establishing, operating, and improving an Artificial Intelligence Management System (AIMS).

Its goal is to ensure responsible and ethical use of AI, manage AI-specific risks such as bias, opacity, and security vulnerabilities, and secure transparency and trustworthiness.

Why Prepare for AIMS Certification Now?

Competitive Advantage: Signals to OEMs and the market that you meet the highest AI governance standards.

Risk Management: Proactively addresses AI bias, data security, and algorithm vulnerabilities.

Trust Building: Enhances trust and brand image with customers and regulators.

Operational Efficiency: Systematizes data, roles, and responsibility management.

Regulatory Readiness: Prepares for evolving global regulations such as the EU AI Act.

Standard Structure and Core Requirements

ISO/IEC 42001 is based on the PDCA (Plan-Do-Check-Act) structure, similar to ISO 9001 and IATF 16949, making integration with existing quality and safety standards straightforward.

Clause | Core Requirement | Automotive Industry Example |

|---|---|---|

Organizational Context | Identify AI-related internal/external issues and stakeholder needs, define scope | Analyze OEM strategies, regulations, and tech trends; define products/processes under AIMS |

Leadership | Executive commitment, policies, clear roles/responsibilities | CEO/CTO announces “Responsible AI Policy” and assigns departmental leads |

Planning | Identify risks/opportunities, set AI objectives | “Reduce pedestrian detection bias by 15% in Q4” |

Support | Resources, training, documentation | Train developers/data scientists; manage data/model documentation |

Operation | AI risk/impact assessment, control implementation | Privacy impact analysis for driver monitoring; apply Annex A controls |

Performance Evaluation | Monitoring, measurement, internal audit | Check accuracy/bias metrics, operate independent audit team |

Improvement | Continual improvement, corrective actions | Root cause analysis, retraining, data enhancement |

ISO/IEC 42001 Certification Roadmap for Tier 1/2 Suppliers

Step 1: Preparation and Planning

Leadership & Team Formation: Secure top management support; involve R&D, quality, IT, legal, HR.

Scope Definition: Decide whether to include only products (e.g., ADAS module) or also manufacturing AI.

Gap Analysis & Awareness Training: Compare current processes with standard requirements; train employees on roles/responsibilities.

Step 2: System Development and Execution

AI Policy & Objectives: Set measurable goals (e.g., “100% traceability of training datasets”).

Risk & Impact Assessments:

Impact Assessment (8.4): Analyze potential societal and personal impacts (e.g., privacy).

Risk Assessment (8.2): Identify AI-specific risks (data, models, security, ethics).

Control Implementation: Apply Annex A/B procedures for data management, lifecycle, stakeholder communication.

Documentation: Maintain required documents (policies, assessment results, training records).

Step 3: Evaluation and Certification

Internal Audit & Management Review: Validate operational compliance and performance before reporting to executives.

Corrective Actions: Investigate nonconformities and implement prevention measures.

External Audit: Pass document and on-site audits to obtain certification.

Integrating ISO/IEC 42001 with Existing Quality and Safety Systems

When combined with IATF 16949, ISO 26262, and ISO/SAE 21434, ISO/IEC 42001 maximizes its impact—integrating quality, safety, and security activities into one governance system to prevent duplication and omissions.

IATF 16949 (Quality): Extend FMEA to include AI-specific failure modes (bias, noise, poisoning, hallucination, overfitting, adversarial attacks). Incorporate AIMS risk/impact results into APQP and control plans.

ISO 26262 & ISO 21448 (SOTIF, Functional Safety): Address malfunction and insufficient performance risks. Apply Annex B.6 (AI lifecycle integration) and B.7 (data scenario coverage, bias removal, completeness).

ISO/SAE 21434 (Cybersecurity): Link TARA threat analysis with AIMS risk assessment. Include data integrity, model robustness, security-by-design, and secure OTA processes.

ASPICE and ISO/IEC 42001 Integration: Enhancing AI Development Maturity

ASPICE evaluates automotive software development maturity. The new ASPICE for Machine Learning adds AI-specific processes:

MLE.1: ML Requirements Analysis

MLE.2: Architecture Design

MLE.3: Training

SUP.11: Data Management

AIMS provides the “what” and “why” of AI governance, while ASPICE for MLE defines the “how.” Running a mature AIMS naturally supports achieving higher ASPICE for MLE capability levels, ensuring AI quality, safety, and trustworthiness throughout the lifecycle.

Table 2: Integration Management Points Between Key Automotive Standards and ISO/IEC 42001 (continued)

Automotive Standard | Core Processes / Tools | Related ISO/IEC 42001 Clauses | Integrated Implementation and Considerations |

|---|---|---|---|

IATF 16949 | FMEA / Risk-based Thinking | 8.2 AI Risk Assessment, 8.4 AI System Impact Assessment | Add AI-specific failure modes (bias, data drift, adversarial attacks) to existing FMEA. Reflect AI impact assessment results in the Severity (S) scoring of the FMEA. |

ISO 26262 / ISO 21448 (SOTIF) | HARA / SOTIF Analysis / Safety Assurance | Annex B.6 AI System Lifecycle, Annex B.7 AI Data Management | Include HARA and SOTIF analysis in formal procedures. Ensure scenario coverage and completeness in data management. |

ISO/SAE 21434 | TARA / Cybersecurity Assurance | 8.2 AI Risk Assessment, Annex A.2.6 Information Security | Integrate TARA threats (model inference, adversarial attacks) into AI risk assessment. Include controls for data integrity, model confidentiality, and availability in information security policies. |

Automotive SPICE (ASPICE) | Software Development Process Assessment | Overall AIMS processes (especially Clause 8, Annex B) | Link AIMS operational processes to ASPICE for MLE requirements. Avoid duplication of documentation and work products, and improve process maturity. |

AI Era: The Time to Act Is Now

AI is now an unstoppable force in the automotive industry. ISO/IEC 42001 is designed to balance AI’s risks and opportunities in increasingly complex technical environments. It is not merely a regulatory shield but a strategic tool for embedding a trustworthy AI culture into your organization and turning it into a competitive advantage.

For Tier 1 and Tier 2 suppliers, now is the time to start—from raising executive awareness to conducting process gap analyses. In fast-changing technological transitions, companies that adopt standards first will become industry leaders and preferred OEM partners.

Hermes Solution is ready to help you move beyond survival to achieve sustainable growth in the AI era.